Ford plans new wave of affordable EVs

Ford will launch at least five new electric models in the next few years including a pick-up, family hatchback and three-row SUV as it looks to boost its EV offering.

The Blue Oval’s electric revival will begin with a compact pick-up truck due to launch in 2027 and challenge the budget-priced Slate Truck in Ford’s United States home market.

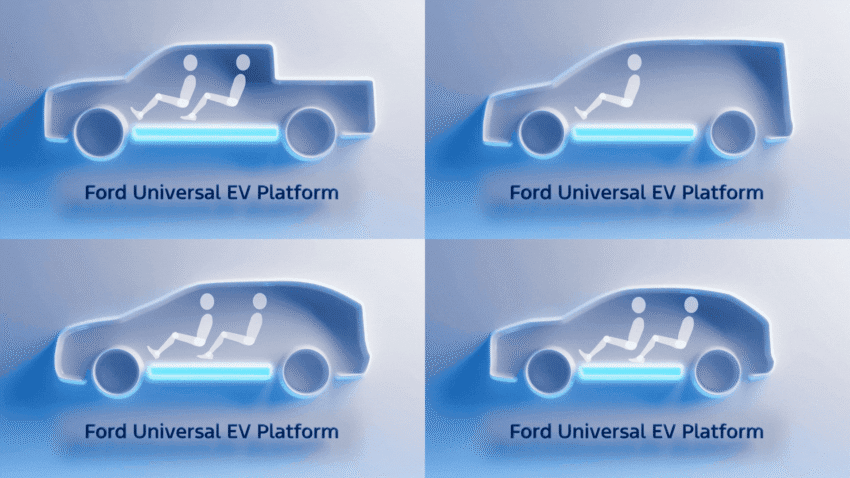

In a move that boss Jim Farley said was as important as the launch of the Model T, the truck, along with all of the new EVs will be based on a new Ford Universal EV Platform and will be built at the company’s massive Louisville plant in Kentucky.

Ford is investing $2 billion in the Louisville factory alongside a $3bn investment in the BlueOval Battery Park in Michigan, with a focus on making its electric models more affordable.

It claims its new range of EVs will bring “affordable, high-quality electric vehicles within reach for millions around the world” without scrimping on equipment, comfort or technology.

Spearheading the new assault is the four-door mid-sized pick-up truck which Ford says will cost from $30,000 dollars (£22,000), offer the pace of a Mustang EcoBoost and more passenger space than a Toyota RAV4.

Following that a five-seat SUV, cargo van, family hatchback and three-row full-size SUV all appear to be on the cards.

While the cars will be built in the US, Ford’s announcement suggests they will be sold beyond its US homeland. Farley supported this idea when he described the new Universal EV Platform cars as “from Kentucky to the world”.

‘Model T moment’

Central to the new wave of Ford EVs is the Universal EV Platform, built using a new “Universal EV Production System”. This uses three parallel production lines in an “assembly tree” rather than a single long line. Front and rear sections will be assembled on independent lines using gigacasting techniques before being connected to the structural battery component, which will already include much of the cabin and interior.

Ford says the process uses 40% fewer workstations and is 15% faster than traditional assembly processes. The platform reduces parts by 20% compared with a typical vehicle and allows multiple vehicle sizes and designs to be built on common architecture.

The platform will use lithium-ion phosphate (LFP) batteries which are cheaper and more robust than NMC batteries which rely on expensive rare earth metals. They will be constructed entirely at the Michigan factory rather than imported from China – something Ford was very keen to highlight.

In a speech sure to please US President Donald Trump, Farley said: “We took a radical approach to a very hard challenge: Create affordable vehicles that delight customers in every way that matters – design, innovation, flexibility, space, driving pleasure, and cost of ownership – and do it with American workers.

“We have all lived through far too many ‘good college tries’ by Detroit automakers to make affordable vehicles that ends up with idled plants, layoffs and uncertainty. So, this had to be a strong, sustainable and profitable business. From day one, we knew there was no incremental path to success. We empowered a tiny skunkworks team three time zones away from Detroit. We tore up the moving assembly line concept and designed a better one. And we found a path to be the first automaker to make prismatic LFP batteries in the US.”